BR2 series down-the-hole drill bits

BR2 series down-the-hole drill bits are made of alloy steel and high-quality alloy steel with advanced heat treatment to ensure good drilling performance and long service life. It is widely used by customers all over the world.

$1,300

Advantages of BR2 low and medium wind pressure DTH drill bit

Long bit life

The BR1 drill bit of this model is made of alloy steel material, which has a long service life and is higher than similar products.The wear ratio of cemented carbide is more than 10-20 times that of similar products, so the life span is greatly extended.

Good compliance effect

The BR1 drill bit uses impact and shear to break the rock, and the drilling speed is stable. The drill bit has strong wear resistance and good gauge performance, which can make the cutting teeth efficiently used.

High drilling efficiency

The drill teeth are wear-resistant, so that the drill bit can always remain sharp, and the hard alloy has high hardness and wear resistance, and the drill bit can always remain sharp, thus greatly improving the tooth feed speed.

Wide range of use

Practice has proved that the drill bit is suitable for drilling in soft and medium-hard (rock formations with drillability below grade 9). Compared with ordinary drill bits, especially for drilling rocks of grade 6-8, the effect is particularly significant.

BR2 down-the-hole drill bit alloy tooth profile selection

- Bullet teeth

Application: The middle teeth of down-the-hole drill bits are suitable for rocks with medium abrasiveness and medium hardness. Edge teeth can also be used when the rock is relatively soft.

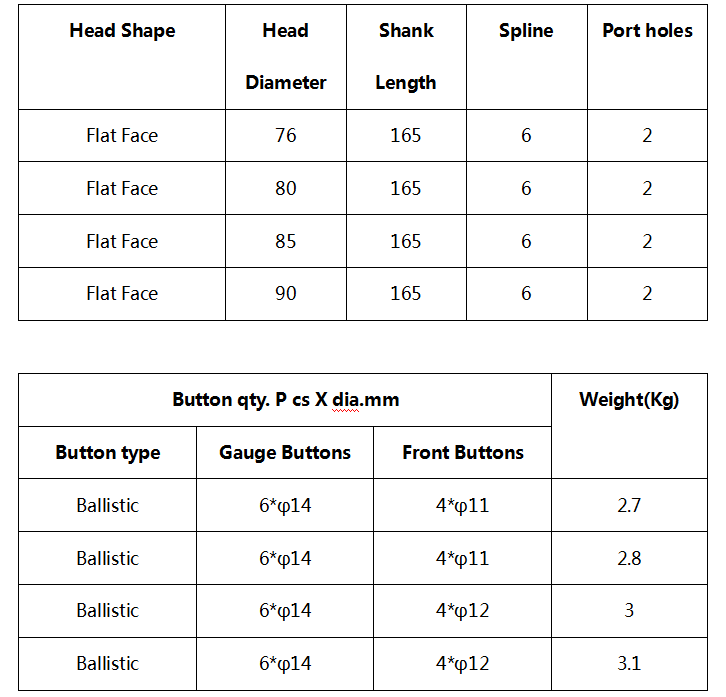

Technical parameters of BR2 down-the-hole drill