SP1080 high-pressure down-the-hole drill bit is a convex-concave drill bit, which has been widely used in geological prospecting, water conservancy and hydropower, highway, bridge and other construction work.

Application of SP1080 down-the-hole impactor

SP1080 DTH drill bit features advantages

Long bit life

This drill bit is relatively wear-resistant in the actual working process. Because the wear ratio of the drill bit’s cemented carbide is more than 10-20 times that of similar products, the service life of the bit has been greatly extended.

Wide range of use

Practice has proved that the bit is suitable for drilling in medium-hard formations such as carbonate rock, limestone, chalk rock, clay rock, siltstone, and sandstone.

High drilling efficiency

This drill bit has high hardness and wear resistance, and the drill bit can always remain sharp, which greatly improves the gear feed speed. While the drill speed is high, the user experience is good, which improves user satisfaction.

Cost-effective

Because this drill bit has a fast drilling speed and long life, the number of drilling times is small, the drilling cost is greatly reduced, and it has an excellent cost performance. It is a good choice.

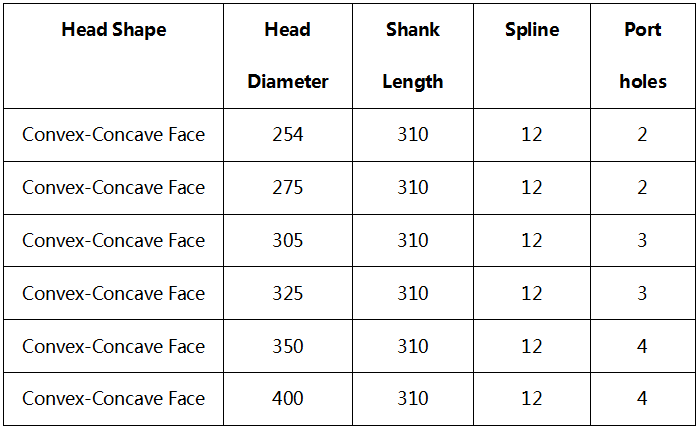

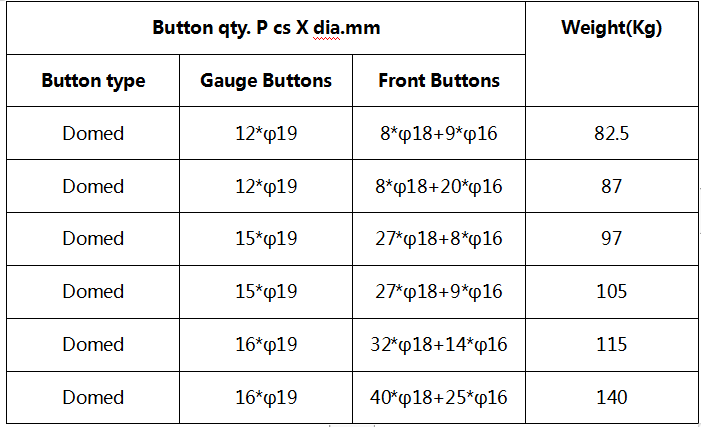

SP1080 bit technical parameters

SP1080 drill product introduction

The SP1080 down-the-hole impactor is connected to the drilling bit for drilling engineering. SP1080 uses high-quality steel and best-level alloy steel as raw materials, special heat treatment technology and advanced cemented carbide inserting technology, so that the drill bit can perform well even on hard rock formations, while saving energy.

This type of drill has a wide range of applications. Compared with ordinary drills, especially for drilling into 6-8 rock formations, the effect is particularly significant.

Alloy tooth profile selection

- Button

Application: DTH drill bit side teeth, suitable for abrasive and very hard rock.

- Parabolic tooth

Application: The side teeth and middle teeth of the down-the-hole drill bit are suitable for medium abrasive and relatively hard rocks.

- Bullet teeth

Application: The middle tooth of the down-the-hole drill bit is suitable for rocks with medium abrasiveness and medium hardness. Edge teeth can also be used when the rock is relatively soft.

- Sharp teeth

Application: The middle tooth of the down-the-hole drill bit is suitable for soft rock formations with high drilling speed and low tooth fracture.

- Flat tooth

Application: Protect the teeth of the side of the down-the-hole drill bit to reduce the wear on the surface of the bit body.