SP882 product description

SP882 high air pressure hammer is combined with down-the-hole drills and down-the-hole drill bits, and is mainly used in engineering construction such as mines, marble, quarry blasting, and water well drilling.

Advantages of SP882 high wind pressure hammer:

No tailpipe design

The drill used in this hammer has no tail tube, which eliminates the damage caused by thermal expansion and contraction of the hammer bit during work and during transportation, and improves the experience of using the hammer.

Energy saving

This hammer has a reasonable design, adopts the optimal air distribution size, cavity design and air tightness, achieving the goal of energy saving and environmental protection. The system of the hammer has low air consumption and fuel saving by more than 10%.

high efficiency

The impact frequency of this hammer is faster than the same period last year, and the drilling speed is more than 15% faster. Compared with the same period, the piston is thinner, the impact work is large, the punching efficiency is high, and the working efficiency of the hammer is higher and more excellent.

The parts and components of this hammer are made of good materials. The piston material is all imported special steel. The advanced heat treatment process is applied during casting and the surface of the hammer is strengthened, which effectively enhances the wear resistance of the hammer.

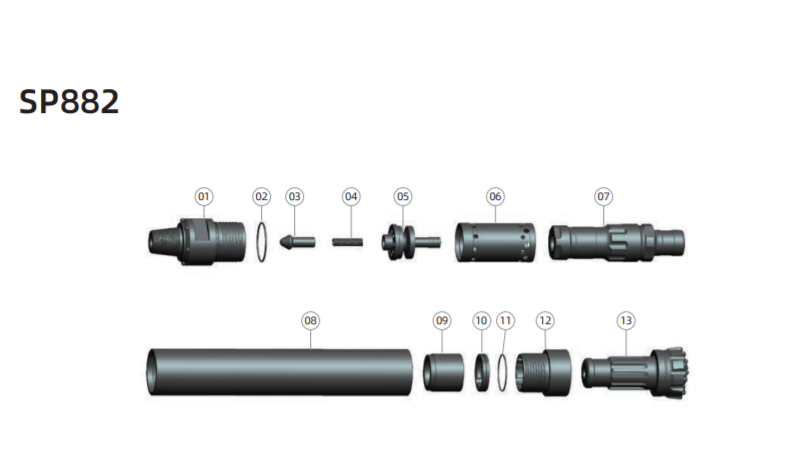

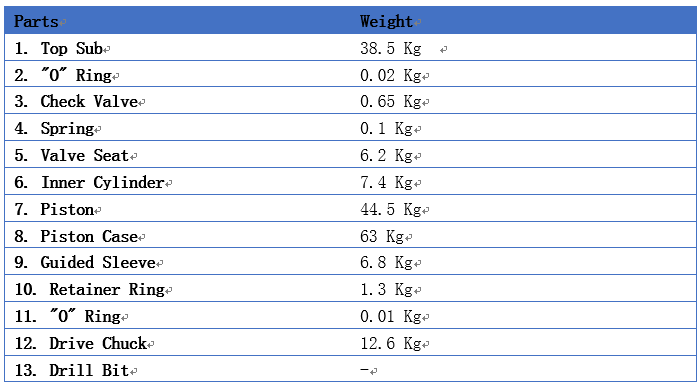

hammer structure diagram

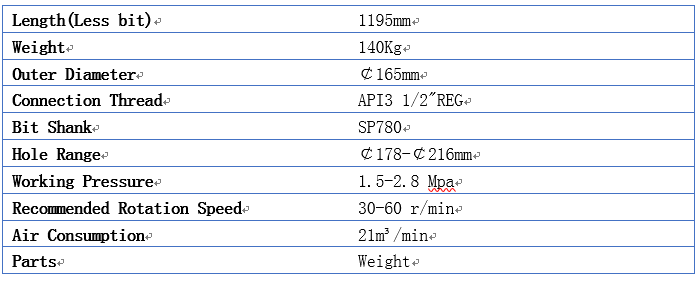

SP882 high wind pressure hammer technical parameters

Application scope of high wind pressure hammer

In actual production, this hammer is recommended to be used in geotechnical engineering to pierce all kinds of tough rocks with poor drillability such as medium and high hardness (depending on the type of hammer used). It is widely used in mining, Engineering holes such as anchoring,quarry, hydrology, water well holes and other fields.