DHD has tail tube series hammer

DHD340 is a valveless high-pressure hammer. The hammer is equipped with a nylon tube drill bit. This high-pressure down-the-hole hammer has high working efficiency and long service life.

Advantages of DHD340 hammer

Superb design technology

This hammer used rock drilling theory for reference in the design, and designed the internal structure size of the hammer, so that the hammer can obtain ideal energy transmission. The hammer has large single impact power, high impact frequency, lower air consumption, and energy saving. Environmental protection.

Easy to disassemble

This hammer uses few parts, has a simple structure, and all parts are hardened. Therefore, the hammer has a long working life, few failures, and convenient maintenance. The connector and clamp sleeve of the hammer are connected with the outer cylinder by threads, which is easy to disassemble.

Good performance

This high-wind pressure tailpipe hammer, using high-quality raw materials and imported processing technology, has more stable performance and longer service life. The hammer adopts domestic advanced heat treatment technology to ensure the good mechanical properties of the hammer.

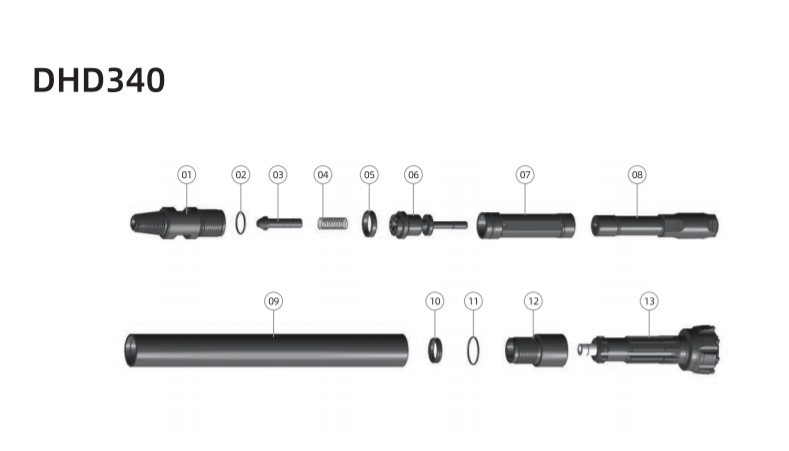

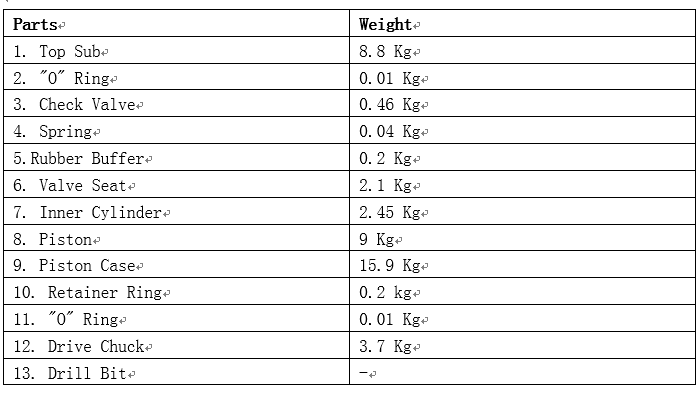

DHD340 has tailpipe hammer structure diagram

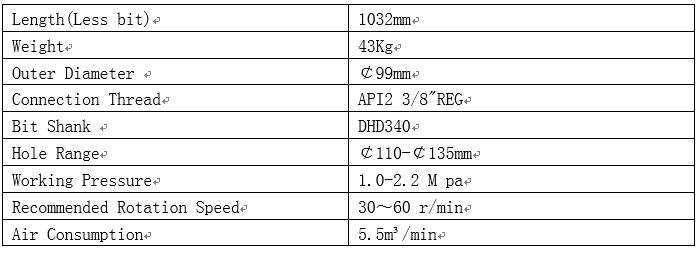

Technical parameters of DHD340 hammer

hammer application range

This type of hammer is widely used in metallurgical, coal, chemical, construction and other engineering drilling operations. It is suitable for dry, feng-shui mixing and blast hole water gushing wet operations. It has reliable working performance and is an ideal blast hole drilling equipment today.

Precautions for assembly, disassembly and maintenance of drilling tools

(1) Ensure that the compressed air is always clean and dry;

(2) Blow clean the air hose before connecting it to the drilling rig;

(3) Ensure that the drill pipe is stored on the pipe rack column.