hammer product introduction

The ND125A tailpipeless high wind pressure hammer has the advantages of fast action, large impact power, low gas consumption and long life. This type of hammer has been widely used in geotechnical engineering to drill various medium-hard and high-hard tough rocks with poor drillability.

Advantages of ND125A hammer

This hammer has no tail tube design, the drill bit does not need nylon tube, thus eliminating the trouble caused by nylon tube fracture, damage and thermal expansion and contraction, effectively avoiding the problems that may occur during the use of the hammer.

The piston of this hammer is of good quality, and the piston material is all imported special steel, so the quality is guaranteed. Using advanced heat treatment technology, the surface of the hammer is strengthened, the wear resistance has been improved, and the feeling of use is good.

This hammer is designed with new rock drilling theory. The internal structure of the hammer is reasonable in size, which enables the hammer to obtain an ideal energy transfer during use. This hammer has large single impact energy, high impact frequency, and higher air consumption. Low and high work efficiency.

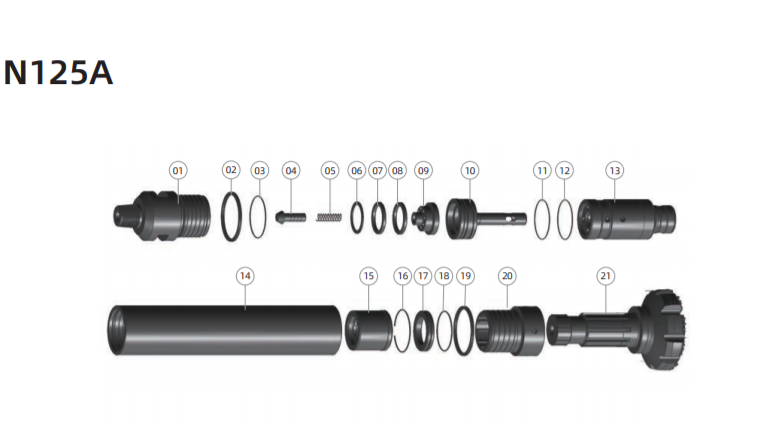

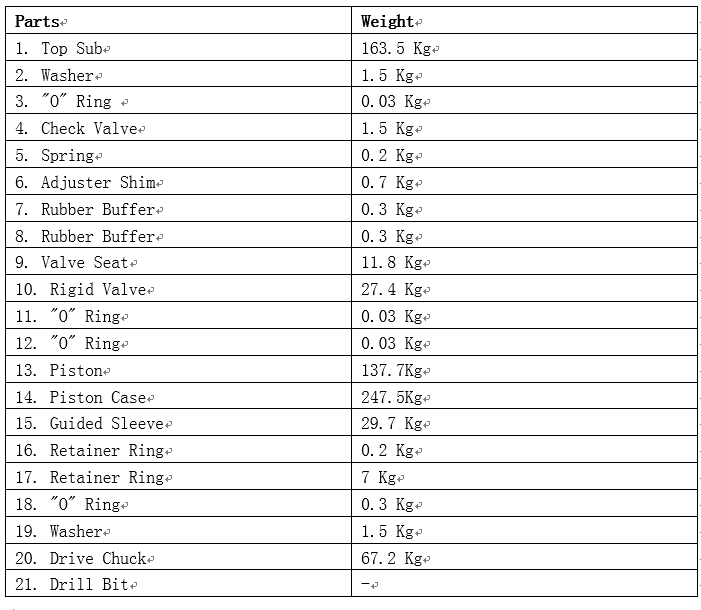

ND125A hammer structure diagram

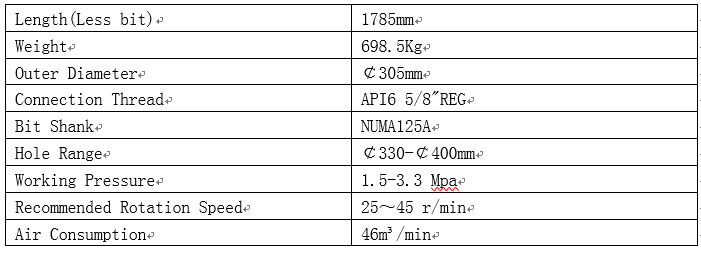

Technical parameters of hammer

Application scope of hammer products

In actual production, it is recommended to be suitable for drilling various medium-hard and high-hard tough rocks with poor drillability in geotechnical engineering. This type of hammer is widely used in mines, quarries, road construction and other engineering drilling blast holes and other fields.