Picture of kszj15 air compressor

Product introduction of air compressor

In order to meet the requirements of the water well industry, a special screw machine for well drilling is specially designed: the oil filling port of the oil tank is outside, which is convenient for refueling. The outer cover and structure are further optimized, and the control system and display are completely optimized and upgraded. It makes the use of well users more convenient, simple and safe.

5/5

main engine

The patented large-diameter rotor design, the main engine and the diesel engine are directly connected through a high elastic coupling, and there is no speed increasing gear in the middle. The speed of the main engine is consistent with that of the diesel engine, with higher efficiency, better reliability and longer service life.

这是一个警报

我是一个描述。点击编辑按钮来改变这个文本。

5/5

Diesel engine

Cummins, Yuchai and other famous diesel engines at home and abroad are selected to meet the requirements of national II emission, with strong power and low fuel consumption. After sales service system covering the whole country is available, and users can get quick and perfect service.

Advantages of air compressor

This type of air compressor is equipped with microcomputer intelligent monitoring air compressor exhaust pressure, exhaust temperature, diesel engine speed, oil pressure, water temperature, oil tank level and other operating parameters, with automatic alarm and shutdown protection functions. Multi stage air filter is suitable for multi dust working environment; multi-stage fuel filter is suitable for domestic oil quality status; super large oil-water cooler is suitable for high temperature and plateau environment.

上一页

下一页

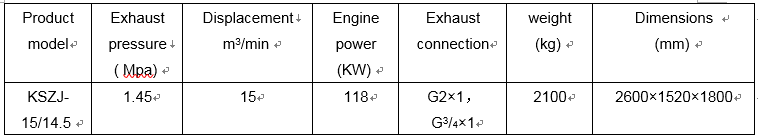

Kszj15 screw air compressor technology for diesel water well

Maintenance method of air compressor

Start the air compressor to run for 5 minutes, so that the oil temperature rises to above 50 ℃, and the oil viscosity decreases. When it stops running, when there is a pressure of 0.1MPa in the oil and gas tank, open the oil drain valve at the bottom of the oil and gas tank and connect it to the oil storage tank. The oil drain valve should be opened slowly to avoid the splashing of hot and pressurized lubricating oil.