Screw air compressor features

- The whole system product adopts National III engine and IP55 motor.

- This series of products are designed for down-the-hole drills, bolt drills, various pneumatic picks, rock drills, shotcreting machines

- and various gas sources required by engineering mines with a diameter of 138mm and above;

- The newly designed intake valve and optimized gas path control system of the series products can make the diesel engine almost effortlessly under no-load condition under the premise of reducing control elements and reducing the source of failure;

- The whole system product adopts National III engine and IP55 motor.

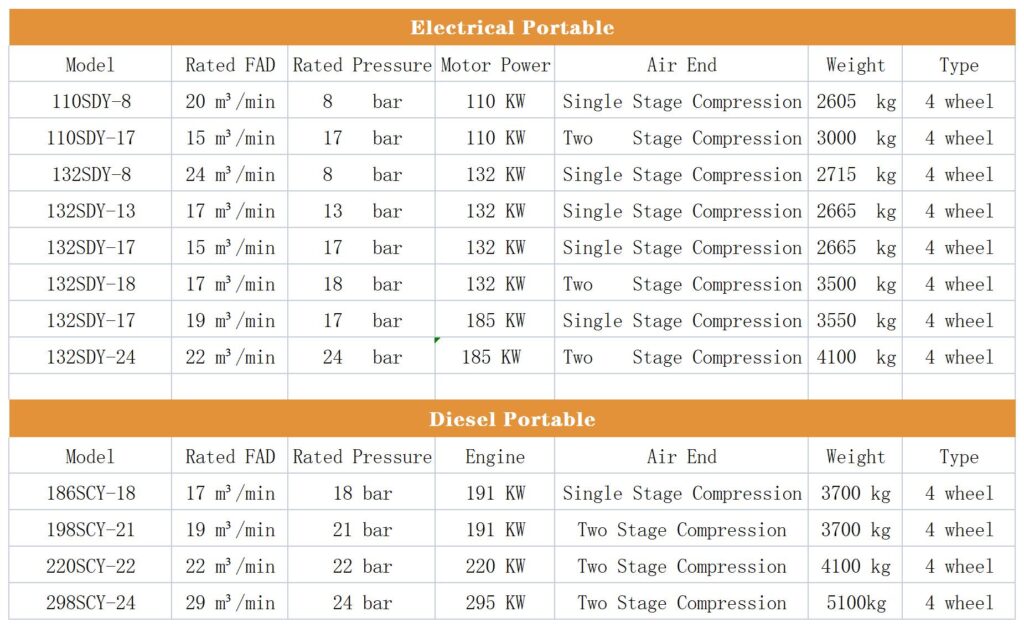

Product Specifications

Daily maintenance of screw air compressor

Usually there are: oil and gas barrel drain, oil level check, peripheral equipment preparation,

Such as water supply and electricity, open the compressor outlet valve, etc.

Air compressors operate in places with many dust particles for a long time, which is easy to produce dirt.

Therefore, the sewage in the air storage tank of the air compressor should be drained cleanly in time.

Some important accessories also need frequent cleaning and maintenance.